Stay live throughout the entire replacement process

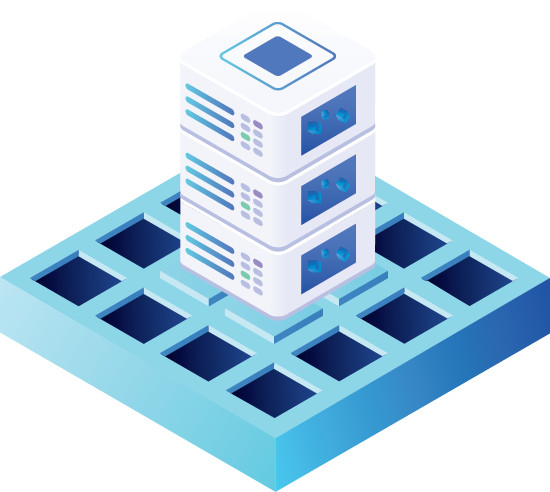

Live Lift is our proprietary service that allows you to replace raised access floor systems without shutting down your server operation. We understand that critical facilities can’t afford to have any downtime, even when it’s time to replace a raised floor. With Live Lift, our team uses our proprietary system to lift one or more server racks or cabinets simultaneously in order to replace the raised flooring tiles underneath them.

What Is Raised Flooring?

Raised flooring is a type of flooring system where the floor is constructed with a hollow space beneath it. This space is usually used to provide access to wiring, piping, and airflow. The raised platform also allows for greater air circulation, which is beneficial for computer rooms and other electronic equipment.

Why service or replace your raised access floor systems

A raised floor is an elevated structural floor above a void where cable management raceways, electrical wiring, and facility cooling systems are located. They are typically found in data centers, offices, call centers, command centers, 911 call centers, libraries, and classrooms. These systems have an average lifespan of about twenty years, but they require ongoing maintenance and attention to avoid weakening of the tiles, which could lead to a partial or full floor collapse.

That’s when our team comes in.

How it works

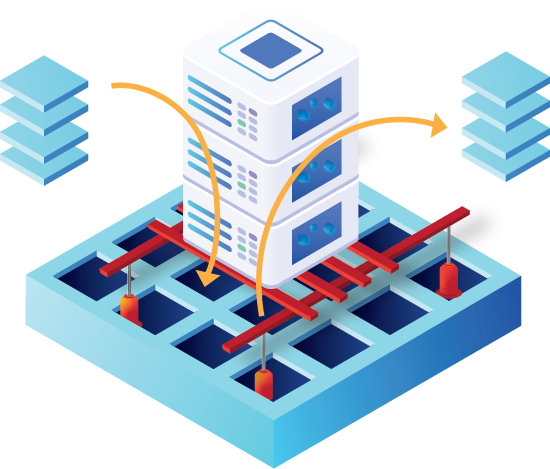

Here’s the process for replacing or repairing your raised floor without shutting down your operation.

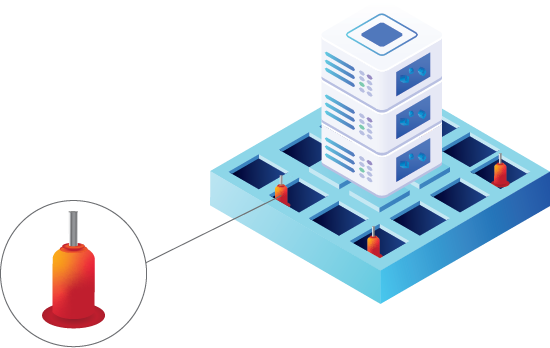

1. We remove the floor tiles

surrounding the server racks.

2. Proprietary support system is

placed on the subfloor.

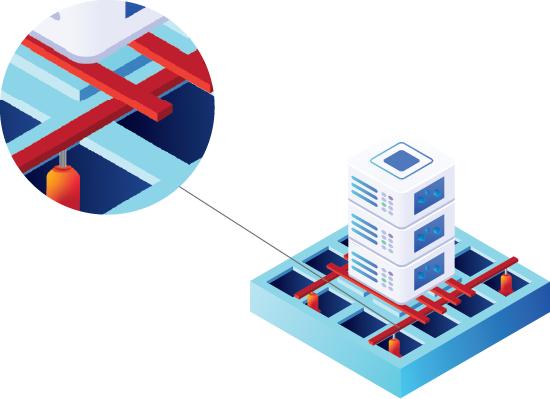

3. We place our mounting system

under the cabinet.

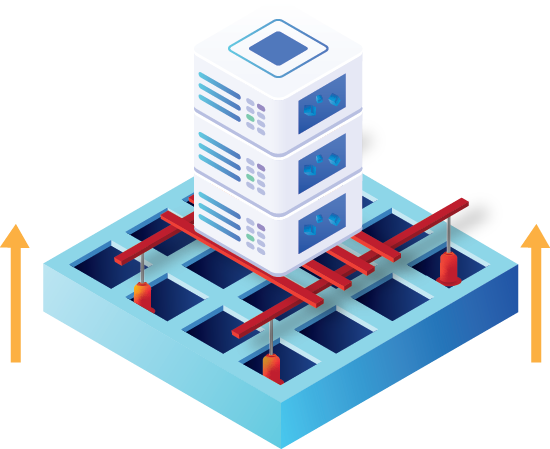

4. Our proprietary system raises the

server rack in unison.

5. We remove the old tiles and add the new ones while the cabinet is lifted.

6. The floor tiles surrounding the

server racks are replaced.

What we do

Critical Facilities Solutions has been installing, strengthening, leveling, and replacing raised access flooring for over twenty five years, and Live Lift Floor Replacement is the culmination of that experience.

Below are the services we offer to help you manage repairs and installations in your facilities. Click each one for details.

Inspections

The weight bearing capacity of your raised floor decreases as pedestals and stringers deteriorate. Our inspectors will evaluate your entire substructure to see whether there are any issues before they turn into large problems.

Live Lift Raised Floor Replacement

We replace your entire floor system or refurbish your existing one with zero downtime for your facility.

Repairs, Strengthening, Leveling

Our team handles leveling, tightening floor panels, panel edging work, and stringer installation between pedestals to provide extra lateral rigidity to the floor.

Floor Grill Replacement

CFS supplies and installs floor grills and perforated panels to match your existing ones or provides ventilation management to a new data center comms room being constructed.

Cable Entry Management

We seal cable entry locations to prevent the escape of cooled air and ensure that your servers stay at the right temperature for efficient operation.

Frameworks

Our team of engineers build and install special frames to support heavy equipment, new units, or to brace an existing support.

Resurfacing Panels

When the cost of a complete raised floor replacement is out of budget, resurfacing the existing floor panels is an option.

Subfloor Sealing

Sealing the subfloor beneath your raised flooring will help prevent the oxidation of concrete and the resulting dust that can damage your ventilation system.

Subfloor Fire Prevention

We can install whole sections of fire retardant products beneath your raised floor, or repair small holes using a variety of different fire retardant materials.

Panel Sourcing, Replication, and Supply

CFS supplies panels of all types and specifications. We offer everything from an extra heavy grade 42mm core to a lighter, office grade 28mm core, in both standard and gridlock types, vinyl, laminate, or bare flooring. All panels are fully tested by a NAMAS accredited lab and are certified as being fully compliant.

What are the benefits of raised floors?

Increased Accessibility

Raised floor systems provide easy access to the underneath cabling and wiring, making it easier to add, move, and change them when necessary.

Enhanced Airflow

Raised floor systems allow for increased airflow and improved ventilation. This helps to keep equipment cool and reduces the risk of overheating.

Improved Cable Management

Properly organized cabling is essential for efficient data centers. Raised floors provide a convenient and organized way to manage cables.

Increased Versatility

Raised floors can accommodate a variety of equipment, making it easy to set up, adjust, and reconfigure a data center as needed.

Enhanced Safety

Raised floors can help to reduce the risk of accidents and injury by providing a safe and secure way to access cabling and wiring.

How should a raised floor be replaced in a data center?

Replacing a data center’s raised floor can be a challenging task, particularly if you want to avoid shutting down your servers. That is why you should contact Critical Facilities Solutions to ensure your raised floor is developed and maintained properly. Here are some steps you can take to replace your data center’s raised floor without disrupting your operations:

Plan Ahead: Plan the replacement project well in advance, so that you can identify the optimal time to replace the raised floor when there is the least amount of server traffic. Consult with your IT team and facilities management to identify the right time to schedule the replacement.

Develop a Contingency Plan: Develop a contingency plan in case something goes wrong during the raised floor replacement. This could include backup power and cooling systems or alternate locations for your servers if needed.

Install Temporary Flooring: Install temporary flooring over the existing raised floor to provide a stable surface for your servers during the replacement process. Make sure the temporary flooring can support the weight of your servers and equipment.

Move Equipment: Move all critical equipment off the raised floor before beginning the replacement process. This may require temporarily shutting down some servers, but it will ensure their safety during the replacement.

Replace the Raised Floor: Once the temporary flooring is in place and your servers are moved, begin the process of replacing the raised floor. Work with a qualified contractor to ensure the new flooring is installed properly and meets your specific needs.

Test and Monitor: Once the new raised floor is installed, test it thoroughly to ensure it is functioning properly. Monitor your servers carefully to ensure there are no issues with cooling or power supply.

By following these steps, you can replace your data center’s raised floor while minimizing disruptions to your operations. Remember to plan carefully and work with qualified professionals to ensure a successful replacement process. Contact Critical Facilities Solution to ensure all the steps above are completed without having to shutdown your servers and operations.

How can I ensure the longevity of my new raised floor?

- Maintain regular cleaning and dusting of the raised floor and its components.

- Inspect the raised floor annually for any signs of damage or potential problems.

- Ensure proper ventilation of the space surrounding the raised floor to prevent the buildup of moisture and humidity.

- Use protective covers when moving heavy objects across the surface of the raised floor.

- Avoid aggressive cleaning agents or solvents when cleaning the raised floor.

Frequently Asked Quetions

What type of flooring system should I use for my raised floor replacement?

The type of flooring system you choose for your raised floor replacement will depend on a number of factors, such as the budget and the purpose of the floor. Some common types of raised flooring systems include steel and aluminum grates, all steel welded construction filled internally with a cementitious core material, and pre-fabricated flooring tiles. Choose a system that meets your specific needs and budget for the best results.

How long does a raised floor replacement typically take?

A raised floor replacement typically takes 1-10 weeks, depending on the size and complexity of the job.

What are the advantages of replacing a raised floor?

- Increased durability: Raised floors are usually made of durable materials such as concrete or metal, which can withstand heavy foot traffic and maintain their shape much better than other types of flooring.

- Increased airflow: Raised floors allow for more efficient air circulation, which helps to keep temperatures consistent and reduce energy consumption.

- Improved cable management: Raised floors provide an easy way to run cabling and wires from one area of the building to another, helping to keep the workspace organized and neat.

- Easier access to subfloor utilities: Raised floors provide easy access to utilities such as electrical wiring and plumbing, which can be difficult to access with a traditional floor.

Contact Critical Facility Solutions to replace your raised floor with zero downtime today!

Critical Facilities Solutions (USA) » Raised Floor Replacement